In recent years, the European Union has introduced new regulations to improve the repairability of consumer goods, aiming to reduce electronic waste and extend the lifespan of household appliances. These changes push companies to make their products easier to repair and maintain, fostering sustainability and greater transparency for consumers.

At the same time, technological advancements offer innovative solutions to facilitate home maintenance. Extended Reality (XR), and particularly Augmented Reality (AR), has emerged as one of the most promising technologies in this field. With interactive instructions and real-time visual support, AR can guide users in diagnosing issues and repairing their appliances, reducing the need for technical assistance and increasing consumer autonomy.

Usability and an easy-to-use interface are essential elements for these tools to be effectively adopted by consumers. Ensuring that AR applications are intuitive and accessible allows end-users to engage with repair and maintenance processes seamlessly, even without technical expertise. The design of XR solutions must prioritise user-friendliness to encourage widespread adoption and maximise impact.

In this article, we will explore the potential of augmented reality in the context of the new European legislation, analysing use cases, benefits, and the challenges of large-scale adoption.

The New European Legislation and the Importance of Repairability

The Right to Repair, which came into effect in the EU in 2024, requires manufacturers to provide spare parts and repair manuals even after the legal warranty period has expired. This regulation aims to reduce planned obsolescence and encourage more sustainable consumption practices.

Manufacturers are now obligated to offer repair services beyond the warranty period, ensuring that essential components remain accessible for at least seven to ten years after a product’s sale. Consumers and independent repairers must also be granted access to repair manuals and diagnostic tools, allowing for greater autonomy in maintaining and fixing appliances. These measures provide numerous advantages, including a significant reduction in electronic waste and cost savings for consumers who no longer need to replace entire appliances due to minor malfunctions. However, the successful implementation of these regulations depends on various factors, including the availability of qualified technicians and the tools necessary for efficient repairs. This is where Extended Reality can play a transformative role.

How EXtended Reality Can Transform Maintenance

EXtended Reality introduces a variety of tools that have the potential to revolutionise the way consumers and technicians engage with appliance maintenance. One of the most promising applications is the ability to overlay visual instructions directly onto appliances, guiding users step by step through the repair process. XR applications can illustrate exactly where to remove a screw or how to replace a filter, reducing errors and making the entire process more intuitive.

Another valuable function of XR is its capacity for remote diagnosis and assistance. Companies can implement AR-based support systems that allow technicians to view the appliance through a user’s smartphone camera and provide real-time instructions. This significantly reduces the need for physical interventions, cutting costs and shortening wait times for repairs. Additionally, Extended Reality enables users to visualise the internal components of their appliances as interactive 3D models, allowing them to better understand their function and identify malfunctions more easily. This feature is particularly useful for complex repairs, such as replacing a motor or an electronic board.

Beyond repair assistance, XR is proving to be an invaluable tool in training both specialised technicians and consumers. Simulating repair scenarios through XR enables technicians to practice procedures without physically dismantling appliances. Meanwhile, consumers can benefit from step-by-step digital guides that eliminate the need for lengthy printed manuals and make learning maintenance techniques more engaging and efficient.

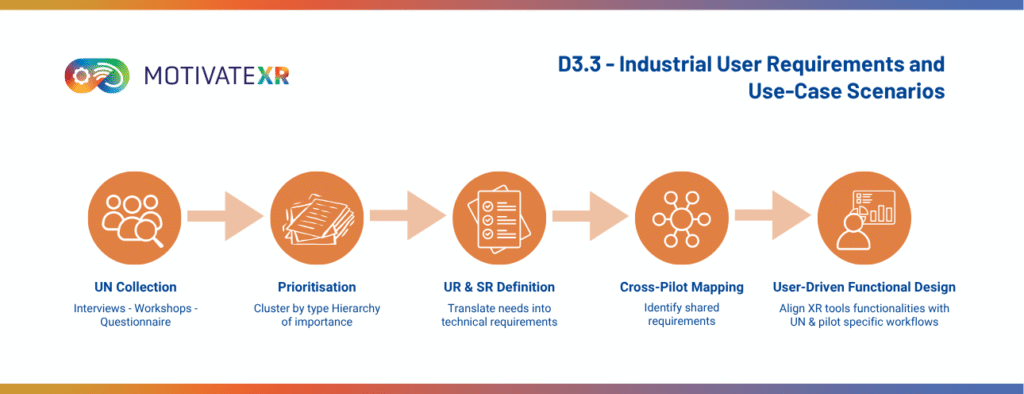

Looking ahead, platforms such as MOTIVATE XR could become an accessible solution for a broad range of users, including DIY communities and small businesses that manufacture consumer goods. Many of these smaller enterprises lack the capital and infrastructure necessary to develop their own proprietary XR software or applications. By leveraging the results of MOTIVATE XR, they could integrate advanced repair and maintenance solutions without significant investments in technology development. This democratisation of XR tools would empower independent repairers, sustainability advocates, and even everyday consumers who seek to prolong the lifespan of their products with minimal external support.

Environmental Impact of Repairability and XR

The push for increased repairability aligns with broader sustainability goals by prolonging the lifecycle of household appliances. As fewer products end up in landfills, the amount of electronic waste is significantly reduced. The European Union estimates that improvements in repairability could cut down millions of tons of electronic waste annually, making XR an essential component in this shift towards sustainability. By empowering consumers to conduct simple repairs independently, XR not only reduces environmental impact but also fosters a culture of conscious consumption, where products are used for their full potential rather than discarded prematurely.

Challenges of Implementation

Despite its immense potential, the widespread adoption of augmented reality in appliance maintenance presents some challenges. One of the primary concerns is accessibility and cost. Not all consumers own AR-compatible devices, and companies must invest in development and training to ensure that these technologies are available and usable on a large scale. Standardisation is another issue, as the vast diversity of appliance models makes it difficult to create a single XR platform capable of addressing all repair needs. Consumer acceptance also plays a crucial role, as many users may initially be hesitant to rely on advanced technology for home maintenance, preferring traditional methods instead.

Conclusion

The combination of the Right to Repair and the integration of Extended Reality presents an unprecedented opportunity to make appliance maintenance more accessible, cost-effective, and environmentally sustainable. By providing interactive and real-time repair assistance, XR empowers consumers to take control of appliance upkeep while helping companies enhance the efficiency of their support services.

While challenges remain, the ongoing advancements in technology and regulatory support create the foundation for a more responsible and sustainable approach to consumption. If properly implemented, augmented reality has the potential to become a game-changer in the way consumers interact with their appliances, fostering greater autonomy and significantly extending product lifespans.

As appliance manufacturers continue investing in AR-based repair solutions, how do you think these technologies could enhance your home maintenance experience? Share your thoughts in the comments!

Documents and Further Reading:

For those interested in learning more about repairability and augmented reality, the following resources provide in-depth insights:

- The European Right to Repair Legislation: details the legal framework supporting consumer rights to maintain and fix their appliances beyond the warranty period.

- The United Nations Environmental Programme’s report on E-Waste: provides an overview of the environmental impact of electronic waste and the importance of repairability in reducing its global footprint.

Author

CETMA – European Research Center for Technologies Design and Materials

Luca Rizzi, Biomedical Engineer and New Product Development Unit Manager at CETMA, focuses on medical product design. He also teaches design technology and has expertise in ergonomics, risk analysis, and CE marking. His team won a Compasso d’Oro Award. He mentors SMEs through the EU’s WORTH Partnership Project and is passionate about design, ICT, 3D printing, and the maker movement.